A historic manufacturer, specialising in stainless steel machining

BEAL INOX, based in Ambert (France), of which SOFRA INOX is the subsidiary, is one of the leading manufacturers of stainless steel fittings and accessories. Over the years, it has been able to adapt to different industrial markets thanks to the competitiveness and quality of its stainless steel parts..

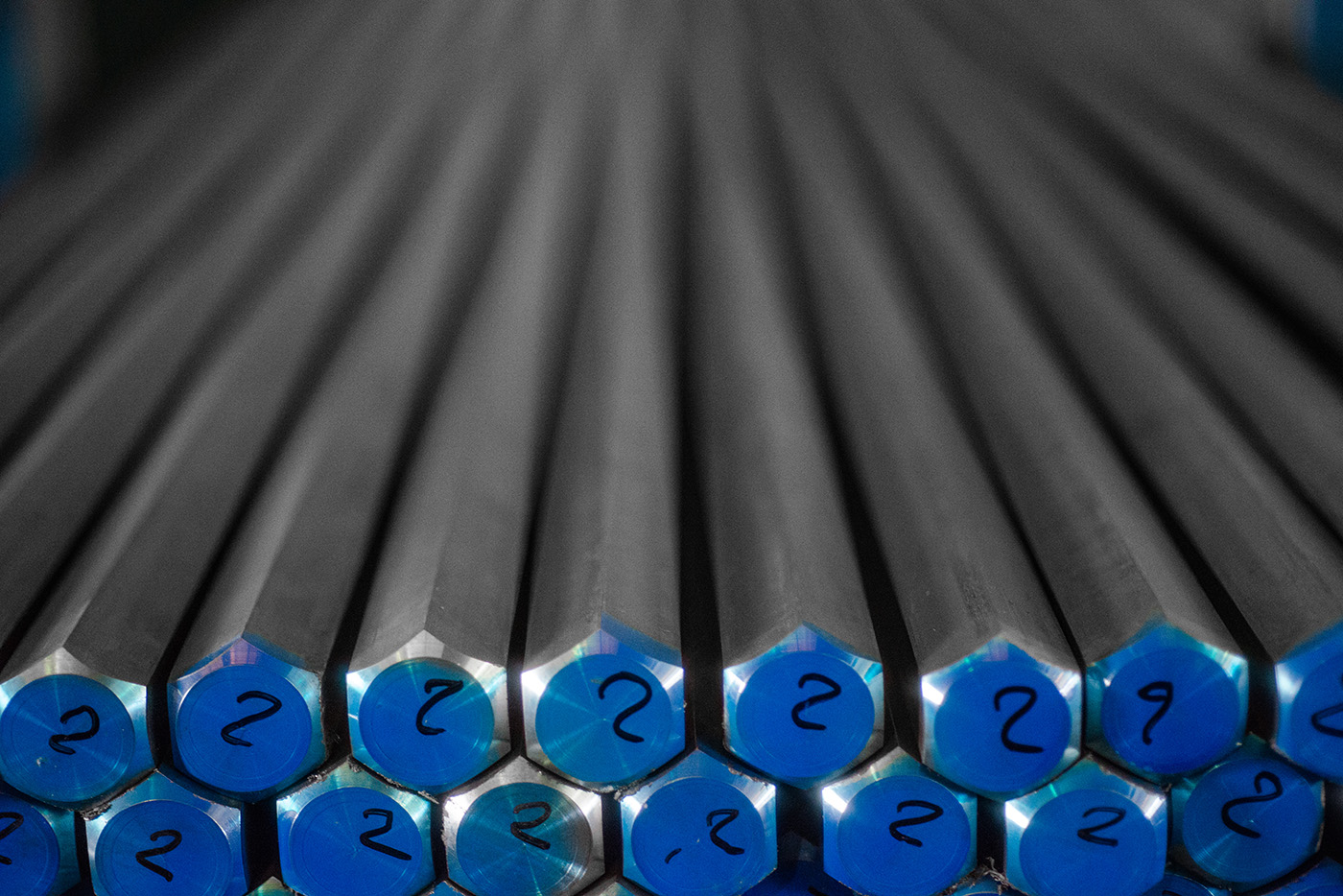

Every year, more than 350 tons of stainless steel are processed... This performance is possible because BEAL INOX's design and manufacturing methods meet the most stringent requirements, and guarantee the durability and quality of stainless steel fittings and parts, as well as their traceability.

The company specialises in machining of stainless steel fittings, using certified materials, by the unit or in small series, to meet the very specific needs of industrialists. The material is checked by spectrometry on the raw material and on the finished part.

BEAL INOX is also one of the few French manufacturers to machine special alloys and superalloys (Inconel®, Hastelloy®, Uranus®, Duplex...) for the creation of special parts, according to drawings.

Many services are offered in addition to manufacturing: laser or mechanical marking, polishing and shining, TIG welding...

Contact BEAL INOX for a custom-made stainless steel part !

Machining of customised stainless steel parts

✔ Made in France ✔ Machining according to drawings ✔ Guaranteed quality

Manufacturing process

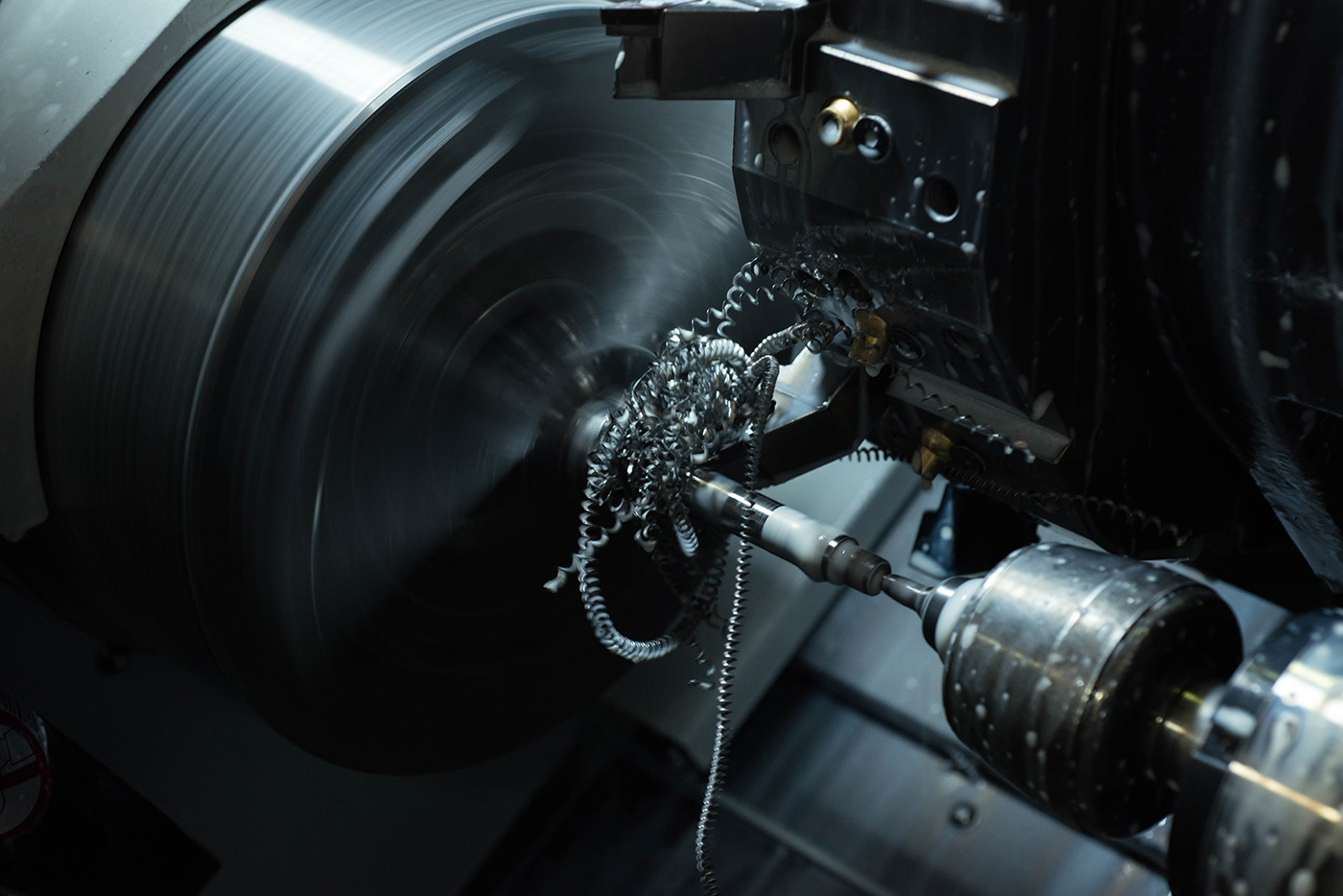

NC turning

Mechanical turning is a mechanical machining process that extracts material to produce cylindrical or conical parts. Today, this operation is carried out by high-precision numerically controlled (NC) lathes.

NC milling

Milling is a manufacturing method where the removal of material is the result of a combination of two movements: the rotation of the cutting tool and the advancement of the workpiece. In our workshop, milling is carried out by numerically controlled (NC) machine tools. These machining centres allow us to obtain stainless steel parts with complex shapes, in small or large series.

Stainless steel welding

Welding ensures a permanent connection between two stainless steel parts. To carry out this operation, our factory has a TIG welding unit (arc welding under an inert gas flow), operated by personnel trained and qualified according to the EN ISO 9606-1 standard.

Marking of parts

Marking a stainless steel part makes it possible to add a logo, a reference, a pictogram... and to personalise the finished product according to the objectives. This operation can be carried out by inkjet printing, micro-percussion or laser marking.